Product Lead

At Jooki I was in charge of the design and hardware development of their second generation music & story player, that encourages kids’ independence and free play with fully customizable audio content. I was involved from the very beginning, going from the very first sketch to seeing the first parts come out of the injection molding tool. Below you can see some parts of this process. With Jooki V2 we improved user experience, production process and created a better product-market fit.

Units sold: 10k

Revenue: €1M

Some of the first sketches and prototypes of Jooki V2. Together with Judicael Cornu (Industrial designer) we gave shape to Jooki V2.

I worked in giving consultancy for the shape and the scenario, all the rest was greatly done by Alyssa as an inhouse relay for the industrial design.

– Judicael Cornu , Industrial Desginer

Several user tests with kids and parents were conducted to find a better UI for kids to place figurines on as well as a recognisable styling of a smart speaker.

I investigated the current customer journey during setup and use of the Jooki app. After defining the current user issues, I tested what the ideal set up would be using some low-fidelity prototypes. I then created a first possible workflow in Adobe XD and went back to the users and repeated this cycle until we had an improved customer journey that I could communicate with our software team.

Some of the sketches and prototypes of the button design are shown. Lot’s of iterations were made to find the right form, styling and functionality for the buttons.

To ensure a qualitative sound, we collaborated with the Sound Hub in Denmark. They have expertise in tuning the sound as well as mechanical integration, as retired Bang & Olufsen engineers are ready to help out over there. I was fortunate enough to visit the Sound Hub twice, to collaborate and get advice from these experts!

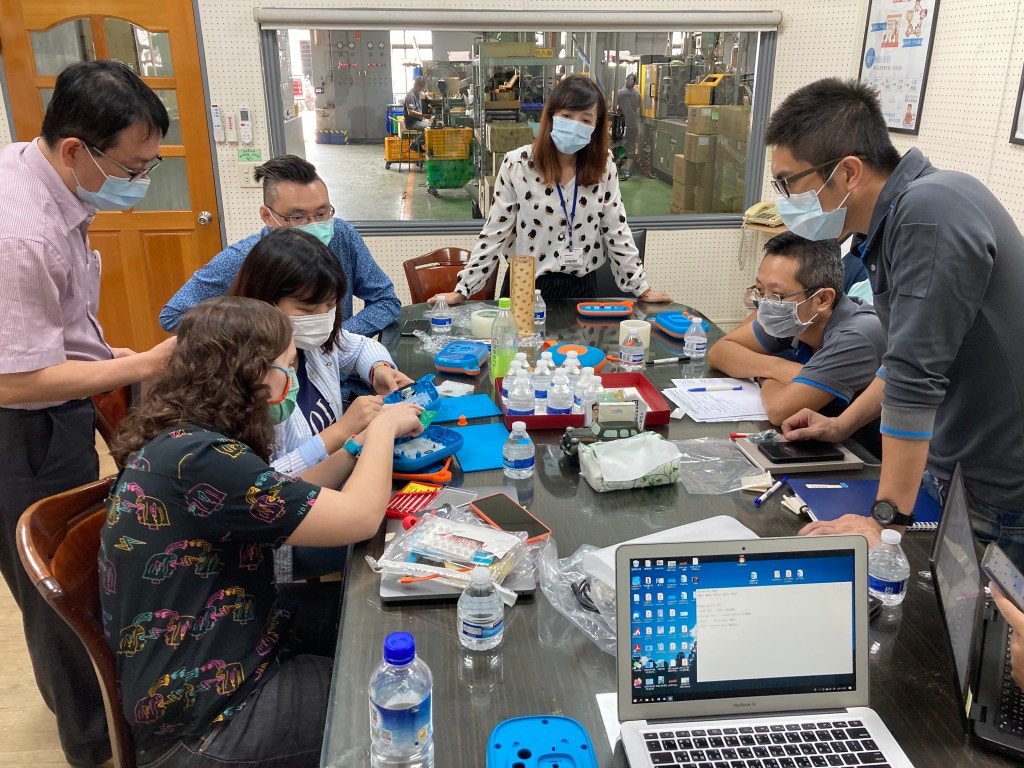

During the corona pandemic I was sent to Taiwan to set up mass production of Jooki V2. I was there for every step of the process going from approving plastic parts, solving assembly issues to going to the official lab to monitor our EMC pretests (see picture on the right). Because of this experience I now have insights in all the steps that are needed to go from an idea to a mass produced product.

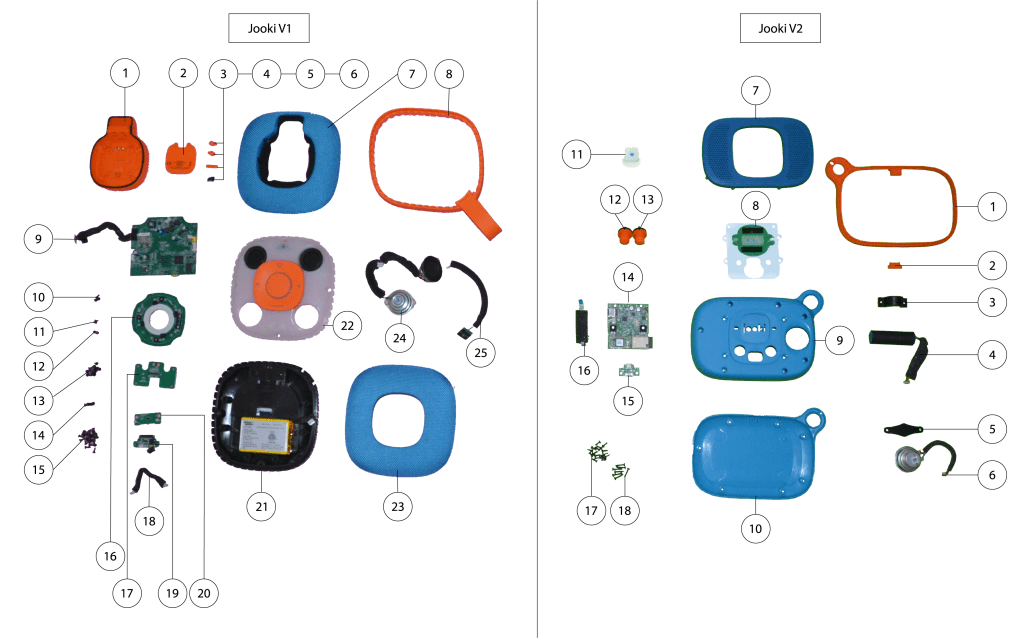

In this picture, all the parts of Jooki V1 and V2 are shown. With Jooki V2 we were able to reduce parts and make an overal simpler design. This creates lots of benefits in cost, assembly and future versions.